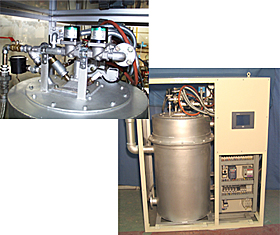

Gas Direct-Firing Small Deodorizer

![]()

Usage

・ Deodorizing and VOC treatment

Features

|

|

High deodorizing efficiency(95% or more) |

|

|

Space saving due to all-in-one unit design including odor fan |

|

|

Energy saving due to exhaust heat recovery |

|

|

Treatments for a wide range of odors and VOC, including ash dust, tar, and mist |

|

|

Wide application for the small business, such as coating, adhesive joining, printing,chemistries, rubbers, foods Best solution for the batch furnace of small coating industry |

Features

| Treatment Volume |

2 Nm3/min.(Max. 200 ℃) |

Dimensions (mm) |

L1050 x W650 x H1425 |

| Fuel |

LNG(13A type) |

LPG |

Weight |

About 350 kg |

| Inlet Pressure |

2 – 5 kPa |

2.8 – 5 kPa |

Odor Fan |

AC 200 V 150 W, Heat proof 260 ℃(Max.) |

| Combustion Capacity |

47 kW(40,000 kcal/h) |

Control Panel |

Integral touch panel |

| Power Supply |

AC 200V, 3 Phase, 50 Hz/60 Hz |

Control |

Proportional control with an inverter |

| Treatment Temperature |

750 ℃ (MAX) |

Safety Device |

Gas/Air pressure limit switch, gas shutoff valve, and flame detector |

Note:Other than this specific equipment, large deodorizer or VOC treating equipment can be produced in the specifications of customer requirements.

Related Product